As most of us know, India is the fastest growing economy in the world. The quarter gone by recorded a growth more than 8% in the fiscal year ended of March 31,2024. Construction and infrastructure sector is a major contributor to this growth, and it gave a huge opportunity for Indian cement producers to increase their sales and revenue. In this article, we are trying to analyze the top 5 players in the Indian Cement Industry, their performance metrics and future growth opportunities.

1.UltraTech Cement

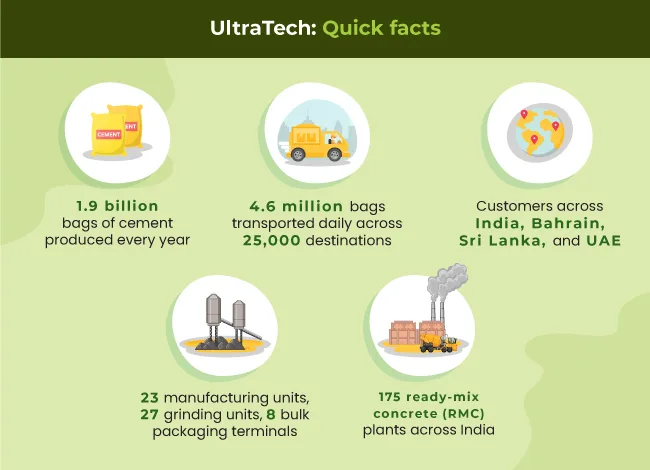

UltraTech cement coming from prestigious Aditya Birla Group, is the largest cement producer in the country. It has a wide distribution network and holds a dominant position in the market.

It has an extensive production capacity, and it caters for diverse construction needs across the length and breadth of the country.

2.Shree Cement

With a strong focus on vertical integration, lean manufacturing practices and operational efficiency, Shree cements command a unique position in the cement industry in India. By strategically placing its manufacturing plants in locations near to the raw material mining, it reduces its overall cost of cement production. The company also emphasizes the sustainable manufacturing processes.

3.ACC Limited

ACC is a legacy in the cement industry, and it has a history of operating in the cement industry for decades in India. Recently acquired by Adani Group, the company commands a significant market share in the country. Its emphasis on innovation and customer-centric approach has helped it maintain a loyal customer base.

4.Ambuja Cements

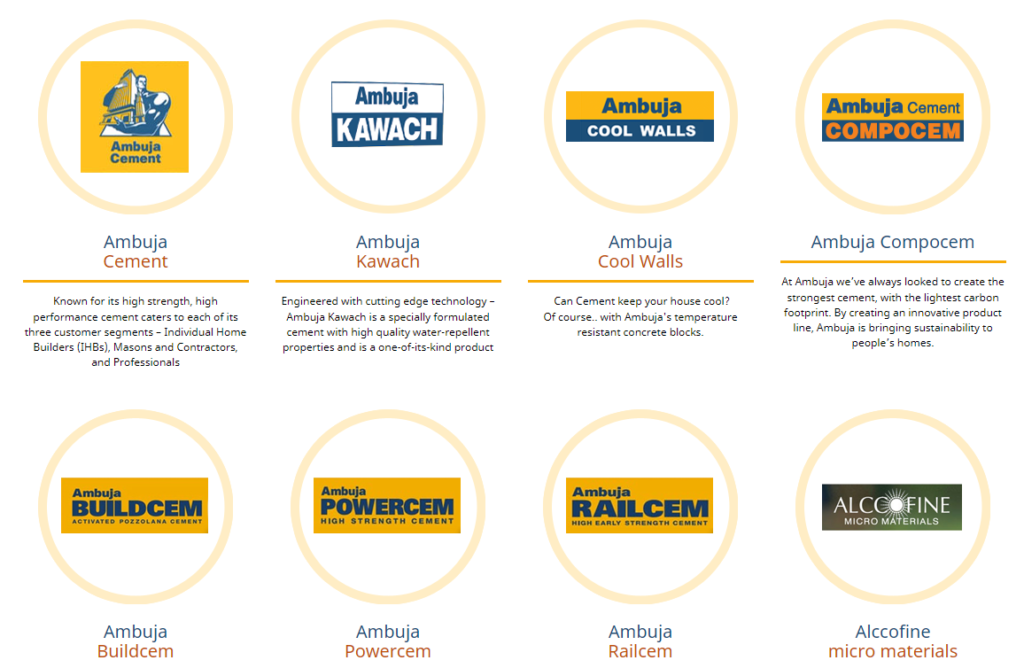

Part of the renowned Adani Group, Ambuja Cements is for its high-quality products and efficient production processes. Ambuja cements focus on the quality of products, innovation, operational efficiency and sustainability.

Main aspects that set apart Ambuja cements are:

High-Quality Products: Ambuja Cements is renowned for its superior quality cement products, which undergo rigorous testing and adhere to international standards. The company’s focus on quality assurance ensures consistency and reliability in its offerings, earning trust and loyalty among customers.

Innovative Solutions: Ambuja Cements continuously invests in research and development to innovate its product portfolio. The company develops specialized cement blends with enhanced properties to address specific construction requirements, such as strength, durability, and sustainability.

Operational Efficiency:

Efficient operations are central to Ambuja Cements’ business model, enabling the company to maintain cost competitiveness and maximize profitability.

Optimized Manufacturing Processes:

Ambuja Cements leverages advanced manufacturing techniques and best practices to optimize production processes. Continuous improvement initiatives, such as lean manufacturing and process automation, enhance efficiency and productivity across its manufacturing facilities.

Supply Chain Management: Ambuja Cements has a robust supply chain network, ensuring timely delivery of products to customers across India. The company strategically locates its manufacturing plants near key markets to minimize transportation costs and improve logistics efficiency.

Sustainability and Environment:

Ambuja Cements is committed to sustainable development and environmental stewardship, integrating eco-friendly practices into its business operations.

Resource Conservation:

Ambuja Cements focuses on resource conservation and energy efficiency to minimize its environmental footprint. The company invests in technologies and practices that reduce energy consumption, optimize raw material utilization, and minimize waste generation.

Carbon Emissions Reduction:

Ambuja Cements actively works towards reducing carbon emissions through initiatives such as alternative fuel usage, waste heat recovery, and renewable energy adoption. The company aims to mitigate its environmental impact and contribute to global efforts to combat climate change.

5.Dalmia Bharat Cement

Dalmia Bharat Cement has witnessed steady growth over the years, driven by its focus on innovation and customer satisfaction. Its diverse product portfolio caters to various segments of the construction industry.

Factors Influencing Future Growth:

Demand Trends:

The performance of cement stocks in India is closely linked to the overall demand for construction activities, influenced by factors such as government infrastructure projects, real estate development, and urbanization trends.

Input Costs:

Fluctuations in raw material prices, particularly those of limestone and coal, can impact the profitability of cement manufacturers. Efficient cost management strategies are crucial for maintaining margins.

Regulatory Environment: Government regulations related to environmental compliance, land acquisition, and taxation can significantly affect the operations and expansion plans of cement companies.

Technological Advancements:

Investments in technology, such as automation and digitalization, play a vital role in enhancing operational efficiency and product quality, giving companies a competitive edge in the market.

Sustainability Initiatives:

With increasing awareness about environmental conservation, cement companies are focusing on sustainable practices such as alternative fuel usage, waste heat recovery, and carbon footprint reduction to align with global sustainability goals.

Market Competition:

Intense competition within the cement industry necessitates continuous innovation and differentiation strategies to maintain market share and profitability.

Conclusion:

While factors such as demand trends, input costs, regulatory environment, technological advancements,

sustainability initiatives, and market competition influence their performance, successful companies demonstrate resilience and adaptability in navigating challenges and capitalizing on opportunities in this dynamic sector.